Project Title: SOC PC power plant control system upgrade

Client: SOC

Site: Brega

Date: 2024

Status: Ongoing

Description: Another big project with Sirte Oil Company. Alshoala is tasked with complete EPC project of control system upgrade of Petrochemical power plant control system. In the scope of this project Alshoala is to replace control system with the new PCS 7 control sytem from Siemens. Apart from the standard Siemens equipment: PCS7 software, S7-410 redundant controllers and Simatic ET200SP HA IO module, in this project we are also installing instruments and CFUs as Siemens latest distributor modules for connection of existing and new instruments. For this EPC project Alshoala has prepared engineering in a form of FDS (functional design specification) and DDS (detailed design specification), and is currently procuring equipment.

![]()

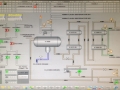

Project Title: SOC Methanol 1a control system upgrade

Client: SOC

Site: Brega

Date: 2024

Status: Ongoing

Description: Another big project with Sirte Oil Company. Alshoala is tasked with complete EPC project of control system upgrade of Methanol 1 plant control system. In the scope of this project Alshoala is to replace control system with the new PCS 7 control sytem from Siemens. Apart from the standard Siemens equipment: PCS7 software, S7-410 redundant controllers and Simatic ET200SP HA IO module, in this project we are also installing CFUs as Siemens latest distributor modules for connection of existing and new instruments. For this EPC project Alshoala has prepared engineering in a form of FDS (functional design specification) and DDS (detailed design specification), procured several batches of equipment (cable trays, cables, Siemens equipment, etc) and is currently installing equipment on the site.

![]()

Project Title: SarirOil Upgrade of HVAC control system

Client: Sarir Oil Operations

Site: Jakhira A91 and Nakhla A107 Oil Fields

Date: 2023

Description: Client intended to replace existing HVAC control system. Project consisted of several control cabinets working both in parallel and as stand alone units. Our team successfully engineered new control system, procured equipment, installed and commissioned system in accordance with client’s instructions and wishes. In addition Alshaola procured and installed new MCBs and motor protections from Siemens LV department.

Used components: 8 Siemens Simatic S7-1500 units, WinCC

![]()

Project Title: SOC Fire detection system in the New Canteen

Client: SOC

Site: Brega

Date: 2023

Description: Commissioning Sintesso fire detection system. SOC fire detection is based on Siemens systems and we supported them with commissioning of the new canteen.

Used components: Sinteso FS2020

![]()

Project Title: SOC Fire detection systems

Client: SOC

Site: Brega

Date: 2023/2024

Description: Commissioning of three CerberusPro Fire detection systems – One in Process Engineering and two in the Workshop Areas. SOC fire detection is based on Siemens systems and we supported them with commissioning of these three systems.

Used components: CerberusPro FS720

![]()

Project Title: Harouge Amal field gas turbine

Client: Harouge Oil Operation

Site: Amal

Date: 2023/2024

Description: Replacement of control system for the old gas turbine at the Amal Power plant. Replacement of DIGICON system with the latest Siemens technology based on S7-1500 CPU.

Despite encounering multiple technical challenges (status of the turbine) we successfully commissioned a new control system allowing Harouge to again use GT1 for the power production.

Used components: Siemens S7-1500, WinCC

![]()

Project Title: Sabratha platform upgrade

Client: Mellitah

Site: Sabratha platform

Date: 2022/2023

Description: At the Sabratha platform, Alshoala has contracted migration of the Siemens WinCC software, Procurement of equipment, installation and commissioning of Siemens system upgrade as well as integration of the system with existing CMMS. The main challenge was working on the oil rig and the very limited timeframe for work during the system shutdown.

Used components: Siemens S7-400H, Siemens S7-1500, WinCC

![]()

Project Title: SOC Gas plant control system upgrade – Training

Client: SOC

Site: Brega

Date: 2023

Description: Operators training was held in Istanbul, Turkiye, for a duration of 3+4 weeks during February, March and May 2023. Participants were 16 Operators and 12 Maintenance engineers from SOC Brega Gas Plant.

The training covered both operation of the system and detailed information about hardware&software needed for the successful maintenance of the system.

![]()

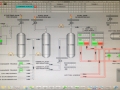

Project Title: SOC Gas plant control system upgrade – Commissioning

Client: SOC

Site: Brega

Date: 2021-2022

Description: The commissioning was done without the total plant shutdown and it was applied gradually in order to limit the effect of works on the production process. Therefore it lasted longer than anticipated but with no significant process disruptions. Upon the client’s request some changes are implemented during the commissioning process itself and project documentation was updated accordingly.

![]()

Project Title: SOC Gas plant control system upgrade – Wiring

Client: SOC

Site: Brega

Date: 2021-2022

Description: Wiring and commissioning of the working plant are not possible without the plant shutdown. Nevertheless, it was agreed with the client that this process will be applied gradually (in phases) in order to limit the effect of works on the production process. Instead of total factory shutdown, it was agreed that one by one SCC will be commissioned while keeping the factory running and taking care of the critical signals.

![]()

![]()

Project Title: SOC Gas plant control system upgrade – Instalation

Client: SOC

Site: Brega

Date: 2021-2022

Description: Following successful engineering and procurement of equipment Alshoala team has finished installation of the equipment at the Gas plant in Brega. This installation consisted of the installation of new cabinets in 10 SCC (Satellite Control Centres) as well as in Main Control and Operation Centre; Installation of fiber optic cable between all sites; Installation of all procured equipment in the new rack cabinets.

![]()

Project Title: SOC Gas plant control system upgrade – Procurement

Client: SOC

Site: Brega

Date: 2021-2022

Description: Following successful engineering of the system we have organized procurement of equipment. All equipment is divided into 4 batches. The first batch was Siemens LV equipment consisting of mostly Rack Cabinets and relays belonging to Siemens LV portfolio. In the second batch, we have delivered the majority of equipment from the Siemens DF portfolio – Industrial PCs, DCS controllers, IO modules and communication equipment. The third batch consisted of Turck safety barriers, while the fourth and final batch consisted of furniture, KVM switches, monitors and other smaller equipment provided by a German Company Hetec.

Technology used: PCS7 DCS software, 10 Siemens Simatic PCS 7 410 redundant CPUs, more than 140 high availability Siemens IO modules ET 200SP HA, Siemens Industrial PCs, Siemens RACK units, Siemens SCALANCE switches, Turck safety barriers, KVM switch.

![]()

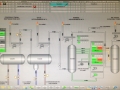

Project Title: SOC Gas plant control system upgrade – Engineering part

Client: SOC

Site: Brega

Date: 2021-2022

Description: Alshoala has contracted the replacement of the whole control system in the SOC Gas plant in Brega. The project has been contracted as an EPC project. The first part – Engineering has been successfully finished in the first half of 2021. Alshoala has designed a new control system consisting of equipment within the Control and operation room (DCS redundant servers, DCS clients, engineering and historian stations, KVM and communication equipment), and field equipment (Siemens redundant PLCs and needed number of IO modules). The customer was provided with contracted documentation and FAT for software was organized abroad.

Importance of the site: Brega Gas plant was one of the first SOC installations, and has been working since the 60s. The previous control system was based on Yokogawa technology from 35 years ago and a new modern system was necessary to allow future operation of the plant.

![]()

Project Title: Upgrade of air compressors’ control system at Wafa Field

Client: Mellitah Oil&Gas

Site: Wafa Field

Date: September 2021

Description: Replacement of the control system for the six air compressors at Wafa oil field. Air compressors are critical installation for the operation of the Wafa Field as compressed air is powering a good deal of process equipment. It is extremely important to keep air compressors running during all times as their stop could lead to the complete site shutdown. There are four main air compressors at the site as well as 2 start-up compressors. Our task was to replace control systems for all six compressors, as well as to replace the main synchronization controller. The project consisted of engineering, installation and commissioning of the equipment. Minor changes in the logic of the system synchronization were applied as a change of request, initiated by the client.

Technology used: Siemens Simatic S7-1200 PLCs.

Importance of installation: Air compressors are powering up this site. At any given time at least two out of four main compressors must be working. Alshoala finished the works before the deadline and without site shutdown.

![]()

Project Title: Replacement of Firefighting control system for SS4 in MOG

Client: Mellitah Oil&Gas

Site: Sabratha

Date: October 2020

Description: Replacement of the existing HIMA control system. This interesting system is based on automation panel rather than a classical fire panel. So replacement is also based on automation system. Scope of this project was engineering, procurement, installation and commissioning of the new Siemens based control system.

Technology used: Siemens Simatic S7 1500 PLC and ET 200SP IO modules, safety barriers.

Challenges: Integration of the existing periphery to the new control system

![]()

Project Title: Upgrade of the inverter system in SOC

Client: Sirte Oil Company

Site: Brega

Date: October 2020

Description: Engineering, procurement, installation and commissioning of inverter system for the Sirte Oil Company. System is based on Benning equipment and consists of modular inverter 13,5kVA, two modular rectifiers 110V/100A, two modular rectifiers 24V/210A, batteries and two distributions. System was prepared by Benning Serbia, transported to Libya and successfully installed and commissioned by our engineers.

Technology used: Benning INVERTRONIC compact Modular, Single Phase Inverters.

Challenges: Installation of this system was crucial for the plant startup. Last-minute adaptations to the system were needed.

![]()

Project Title: Siemens Simatic Training for SOC

Client: Sirte Oil Company

Date: August 2019

Description: Alshoala Engineering Company has organized and conducted three series of trainings for SOC engineers. These courses have targeted wide spectrum of engineers in both operation and maintenance departments, especially those who have the motivation to engage in PLC technology and develop new skills. Training started with basics of the automation field and progressed up to programming of complex tasks using Siemens Simatic S7-1200 units. Especially important aspect of the course was hands-on training on live PLC controllers and specially designed models. Using simple applications trainees were able to understand and learn how to program Siemens controllers themselves.

SOC PR department video

We strongly believe that the right path of progress is investing in knowledge of employees. For this reason we are pleased to have trained SOC engineers. With a new knowledge they will be able to better understand existing systems they have and to foresee future needs of their organization.

![]()

Project Title: Remote operated valve for Ubari power plant – phase I

Client: GECOL

Site: Al-Sharara oil field

Date: April 2019

Description: Installation and commissioning of remotely operated pneumatic valve at Al Sharara oil field. Installation of local control panel from where valve can be operated manually as well as installation of temporary PLC cabinet at the operation room from where valve is operated automatically. Installation of the temporary SCADA system that allow users to operate valve from the PC.

Technology used: Siemens S7-1200, HMI TP900 Comfort panels, WinCC SCADA, pneumatic control valve, pneumatic control system with piping.

Importance of the project: Installation of this valve allows sending required amount of crude oil to Ubari power plant, which is supplying large part of southern Libya with power.

![]()

Project Title: Upgrade of the control system for FMWR Sabratha platform

Client: Mellitah Oil&Gas B.V., Libyan Branch

Site: FMWR Sabratha platform

Date: August 2018

Description: Engineering, procurement, installation and commissioning of control system for drilling process at Sabratha FMWR platform. System is based on Siemens Simatic S7-1500 PLC for monitoring and controlling 4 main motors (2 Mud Pumps, Top Drive and Draw Works), its blowers and washers, and 4 DC drives.

Technology used: Siemens S7-1500, 2 HMI TP900 Comfort panels, 30 different I/O cards.

![]()

Project Title: Replacement of control system for 4 Woma pumps

Client: RASCO

Site: Ras Lanuf

Date: May 2018

Description: Design, engineering, procurement, installation and commissioning of 4 identical control systems for control of Woma pumps at Ras Lanuf refinery. In this way all pumps are unified in operation and in wiring. Main challenge was state of pumps themselves, existing wiring and mechanical issues.

Technology used: Siemens S7-1200, HMI panels

![]()

Project Title: Upgrade of Fire control panel in Zawia

Client: Akakus Oil Operations

Site: Zawia export terminal

Date: August 2017

Description: Removal of old existing fire detection panel, installation of new Siemens Sinteso FC2060 fire detection system, as well as one Siemens XC10 extinguishing panel. Marshaling of two new panels. Replacing part of the collective detectors. Programming new systems to work with the same logic as previous system. Connecting new installed systems to the existing SCADA. Completion certificate.

Technology used: Siemens Sinteso FS2060, Siemens XC10 extinguishing panel

Challenge: Connection of existing detectors, EX proof equipment, Flame detectors, Linear Heat Cables.

![]()

Project Title: Upgrades in Tobruk main oil terminal – Phase C

Client: Brega Petroleum Marketing Company

Site: Tobruk oil terminal

Date: May 2017

Description: Removal of two old panels and obsolete wiring, installation and testing of 4 pressure indicator transmitters and two flow meters with needed wiring on two pipelines. Reprogramming of PLC, HMI and WinCC SCADA taking new instruments in considerations, all according to client’s requirements. Additional new 12” screen with site alarms display was installed and connected to the SCADA.

Technology used: PLC S7-1500, HMI KTP1200 basic, WinCC SCADA

Challenge: The Client demanded all work to be done without shutting down the whole facility.

Importance of the site: This terminal is supplying the whole eastern part of Libya with oil, as well as cargo and oil tankers on its port.

![]()

Project Title: Upgrades in Tobruk main oil terminal – Phase B

Client: Brega Petroleum Marketing Company

Site: Tobruk oil terminal

Date: March 2017

Description: Upgrading heavy oil tank farm and loading arms control from old relays system to fully automated up-to-date PLC control system. Old panels were replaced with new ones, new wiring was run, PLC, HMI and WINCC SCADA were programmed and installed according to client’s requirements.

Challenge: The Client demanded all works to be done without shutting down facility, so it was performed in stages, migrating one tank with its utilities at a time.

Importance of the site: This terminal is supplying the whole eastern part of Libya with oil, as well as cargo and oil tankers on its port.

![]()

Project Title: Upgrades in Sarir oil terminal – Phase A

Client: Brega Petroleum Marketing Company

Site: As-Sarir

Date: January 2017

Description: Upgrading loading arms control from old semi-automated Mitsubishi system to fully automated up-to-date PLC control system. Old panels were replaced with new ones, new wiring was run, PLC, HMI and WINCC SCADA were programmed and installed according to client’s requirements.

Challenge: The Client demanded all work to be done without shutting down the whole facility, so it was performed in 8 stages migrating one loading arm, with its utilities, at a time.

Importance of the site: This terminal is supplying the eastern part of Libya with oil, as well as Sarir power plant.

![]()

Project Title: Upgrades in Tobruk main oil terminal – Phase A

Client: Brega Petroleum Marketing Company

Site: Tobruk oil terminal

Date: October 2016

Description: Upgrading 6.6 kV booster pumps control from old relays system to fully automated, up-to-date PLC control system. Old panels were replaced with new ones, new wiring was run, PLC, HMI, WINCC SCADA were programmed and installed according to client’s requirements. Additional pressure indicators, flow meters and temperature gauges were installed.

Challenge: The Client demanded all works to be done without shutting down the facility, so it was performed in 4 stages, migrating one pump with its utilities, at a time.

Importance of the site: This terminal is supplying the whole eastern part of Libya with oil, as well as cargo and oil tankers on its port.

![]()

Project Title: Gas Plant Emergency Shutdown System

Client: Sirte Oil Company

Site: Sahl Field

Date: 2014

Description: Project includes the complete replacement of the old inoperative August Bonar System (now ABB) with Siemens PCS7, S7400HF system. Scope of works included the study, re-design, supply, installation and commissioning of new fail safe system, complete with training for client engineers. Project also included the replacement of all Zener barriers, interfacing EX rated instrumentation to the control system, alarm archiving server and operator stations.

Importance of the site: Sahl-field news

![]()

Project Title: Gas Compressor Control System

Client: Mabrouk Oil Operations

Site: Mabrouk Oil Field, Sirte

Description: Program modification, testing, commissioning and startup of Gas Compressor control system. Main Controller Siemens Step 7 400H, interfaced to ABB DCS System through Modbus.

![]()

Project Title: IT Data Centre

Client: Akakus Oil Operations

Site: Tripoli HQ

Description: Design, Supply, Installation, Testing and Commissioning of a complete Data Centre housing all the company’s IT Equipment. Scope of Works included the supply and installation of air conditioning system, Fire Alarm, FM200 Suppression System, Very Early Smoke Aspirating System (VESDA), Access Control, CCTV, Power & Lighting, Raised Flooring, False Ceiling and a network management system to monitor all the systems through the corporate network.

![]()

Project Title: PABX Room

Client: Akakus Oil Operations

Site: Tripoli HQ

Description: Design, Supply, Installation, Testing and commissioning of a PABX Room housing the company’s central telephony equipment. Scope of Works included the supply and installation of a Fire Alarm System, FM200 Suppression System, Very Early Smoke Aspirating System (VESDA), Access Control and a network management system to monitor all the systems through the corporate network.

![]()

Project Title: Fuel Forwarding Terminal Control and SCADA System

Client: Brega Petroleum and Marketing Company

Site: Tripoli Airport Fueling Station

Description: Complete design, installation, programming, testing and commissioning of a control and SCADA system for the Tripoli Airport fueling terminal. Hardware included S7-300 Main Controller, PDSIII Pressure Transmitter, Radar Level Transmitters, Rotork Actuator Valves, Oil System Filter, Soft Starters w/Profibus card for main pump and 3x Clamp-on Ultrasonic Flowmeters. WinCC SCADA system for control and monitoring. OP177P for local operation.

![]()

Project Title: Loading Arm Gantry Control and SCADA System

Client: Brega Petroleum and Marketing Company

Site: Benghazi

Description: Complete design, installation, programming, testing and commissioning of a control and SCADA system, to monitor the truck loading operations. Hardware used included a Step 7 300 Main Controller, HMI Basic Color Panel KTP1500, 1x PD Meter and pressure transmitter.